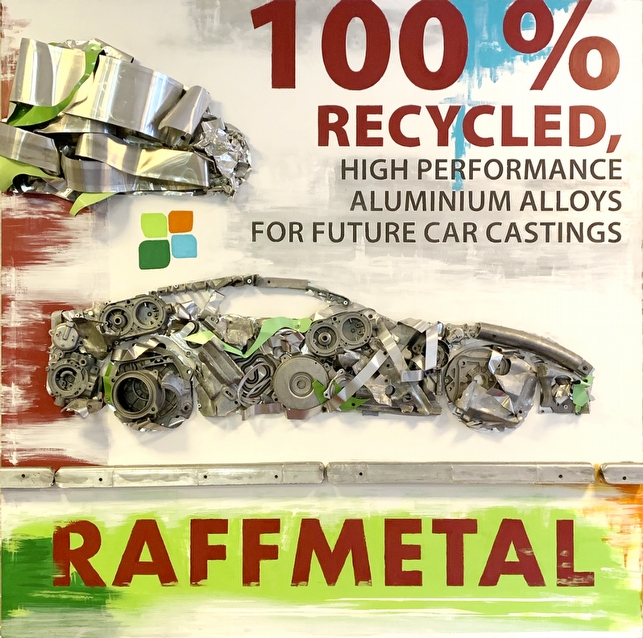

The automotive sector is looking with increasing interest at aluminium as a valuable resource for the vehicles of today and tomorrow. According to a recent Ducker study, the aluminium content in cars is set to increase, bringing major benefits in terms of quality and sustainability:

In order to increase the use of recycled aluminium in cars, close cooperation between the automotive sector and the recycling chain is essential. The main challenge will be to develop new plant solutions to separate metal and plastic alloys for more selective dismantling of materials before shredding, in order to enhance their chemical composition and maintain separate recycling routes, thus ensuring high end-of-life recycling rates.

The use of recycled aluminium alloys has two important advantages in terms of sustainability:

1. -95% ENERGY: energy consumption for the production of recycled aluminium is 95% lower than for the production of primary aluminium.

2. -92.5% CO2 EMISSIONS: the production of recycled aluminium reduces CO2 emissions by 92.5% compared to the production of primary aluminium.

The new guidelines outlined by the European Union in the Green Deal and in the Circular Economy Action Plan define the circular economy as an opportunity to increase Europe's competitiveness by using available resources in the most efficient way possible, mitigating environmental effects and energy consumption especially in terms of CO2 emissions.

Aluminium recycling makes a significant contribution to the circular economy and environmental sustainability:

1. Minimising the exploitation of raw materials upstream, reducing landfill downstream;

2. Ensure significant energy and water savings;

3. Reducing CO2 emissions in order to offer the market products with a low carbon footprint.

The aluminium recycling industry, in the face of continuous plant, environmental and energy investments will give the automotive sector a growing reputation as a leading player in the fight against climate change and the depletion of natural resources.

For more information write to qualita@raffmetal.it