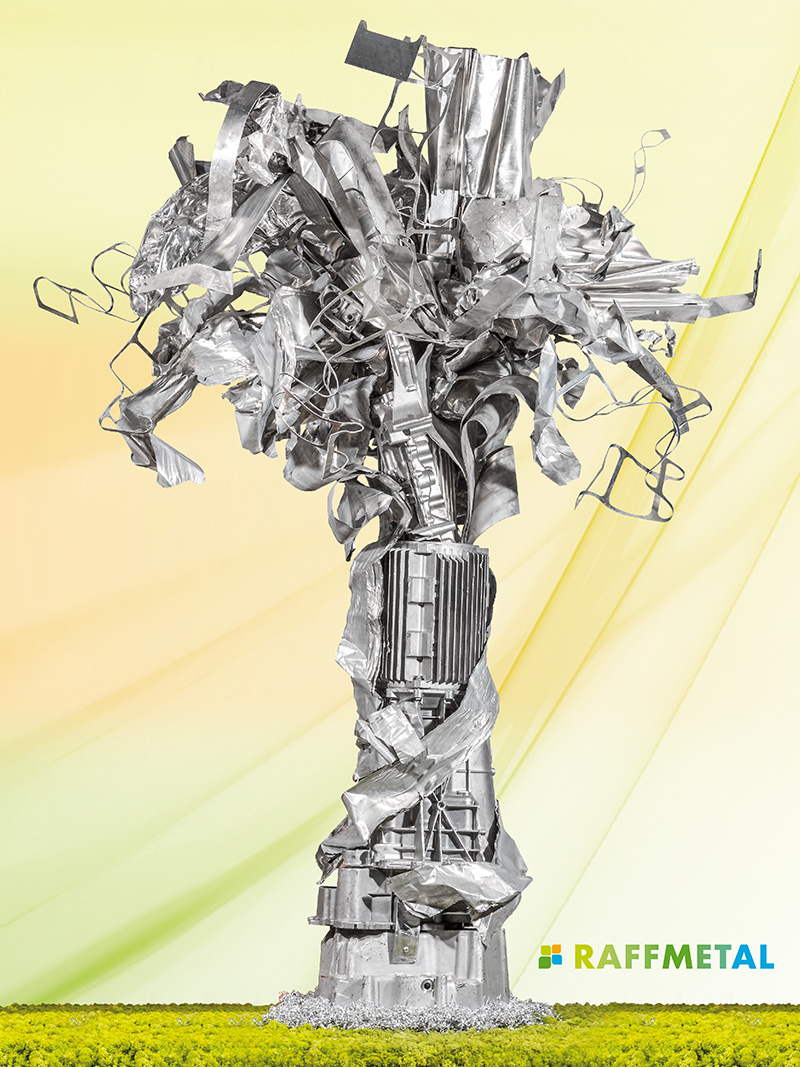

The environment is nature and nature is synonymous with life. To this unique and extraordinary gift,

Raffmetal attributes a value of primary and central importance in selecting its company policies, based on the respect, protection and safeguarding of the ecosystem in which it operates.

Company activity is actually developed on the principle of

100% recycling, playing an important role in saving natural resources and working to eliminate waste that would otherwise be handed down to future generations.

As well as the intrinsic benefits of the company core business, Raffmetal is committed to ensuring that every action is analyzed from the standpoint of environmental protection and safety, in order to achieve results that are not limited to those required by law, but that ensure

maximum protection of nature and the surrounding area, investing voluntarily in its promotion and safeguarding.

Raffmetal and the environment

Aware that company activity must be well integrated in the territory in which it operates and with the conviction that

industrial growth and the protection of the environmental patrimony represent inseparable elements for guaranteeing sustainable development, Raffmetal has always paid particular attention to ecology and the safeguarding of nature.

Constant effort to apply the best available technologies

(BAT - Best available techniques), together with a careful control system and the management of environmental aspects, allowed Raffmetal to already obtain important environmental certification UNI ISO 14001 for all of its productive units back in 2004.

Raffmetal also participates in the limited liability consortium

RAMET (Environmental research for metallurgy), created within the Industrial Association of Brescia and grouping numerous companies that operate in the iron and steel and metallurgy sectors. RAMET promotes studies and research aimed at

reducing the impact of production activities to a minimum by adopting cutting-edge technologies.

In order to further and continuously improve the performance of all environmental matrices, Raffmetal harnesses its qualified internal staff who work with commitment and passion to research and develop new production processes with reduced environmental impact, as well as monitor and improve existing processes. For the same reason, an

internal laboratory, equipped with cutting-edge instruments and equipment, has been designed and built.

The minimization of waste is also a focal point of Raffmetal activities.

For more than 25 years, the by-products of melting have been completely recycled, transforming them into valued materials and eliminating the need to dispose of them as landfill. Atmospheric emissions are constantly monitored and kept well within the limits of the law, while water resources are saved through internal recycling.

Environmental certification

Thanks to its commitment to environmental protection, Raffmetal has been one of the first Italian companies in aluminum industry to achieve the standard ISO EN 14001:2004 in environmental management for all its production units.

In 2015 Raffmetal has decided to continue the implementation and revision of the environmental management system in view of the new edition of the standard ISO 14001:2015.

In 2017 RM got the

UNI CEI EN ISO 50001:2011 certificate. Raffmetal aims, with a systematic approach, at the continuous improvement of all its production units of its energy performance and confirms the constant commitment to a more efficient and sustainable use of energy.